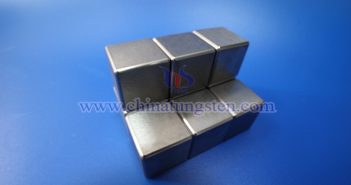

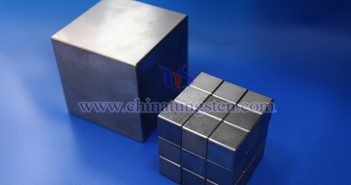

Depending on the application field, the physical and chemical properties of tungsten-copper (W-Cu) alloys, such as shape, raw material ratio, color, and density, vary. Shapes can include cubes, rectangular prisms, cylinders, spheres, tubes, and fine wires. However, under the same raw material ratio and production process conditions, W-Cu alloys of different shapes exhibit similar physical and chemical properties. The following introduces the basic information on tungsten-copper alloy cubes. In terms of definition, a tungsten-copper alloy cube is a two-phase pseudo-alloy…