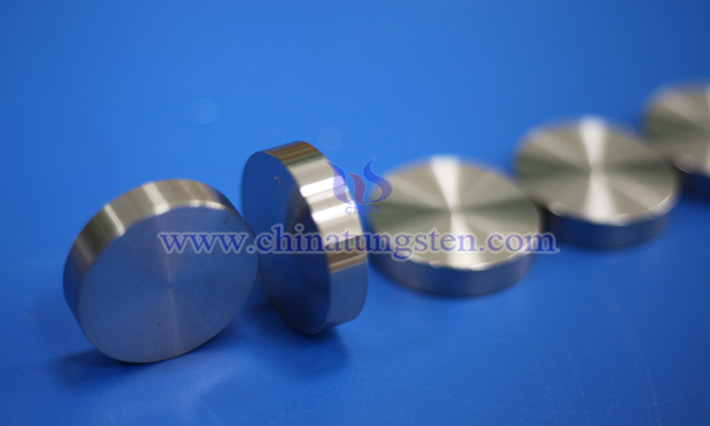

Tungsten alloy discs, leveraging their exceptional mechanical, thermal, and chemical properties, have become a critical high-performance material in the counterweight field. CTIA GROUP LTD tungsten alloy discs primarily consist of tungsten as the core component, supplemented with elements such as nickel, iron, and copper, and are manufactured through powder metallurgy processes. They are widely applied across various scenarios, from precision instruments to heavy equipment.

I. Performance Advantages of Tungsten Alloy Discs

The performance advantages of CTIA GROUP LTD tungsten alloy discs stem from their unique microstructure and elemental composition, enabling efficient weight control and enhanced stability in counterweight applications.

High Density: The density of tungsten alloy discs, typically ranging from 16.5 to 18.75 g/cm3, is one of their standout features—approximately 2.3 times that of steel (7.86 g/cm3) and over 6 times that of aluminum (2.7 g/cm3). This high density allows tungsten alloys to provide significant weight in a compact volume, making them ideal for space-constrained designs. In equipment requiring balance, tungsten alloys achieve optimal counterweight effects with a smaller footprint, avoiding aesthetic or functional impacts from oversized materials.

Excellent Mechanical Properties: Tungsten alloy discs strike a balance between strength and toughness. The addition of nickel and iron forms a uniform solid solution and intermetallic compounds, effectively enhancing the material’s ductility and tensile strength. This property enables tungsten alloy discs to withstand impact and fatigue in high-load and dynamic environments while maintaining structural integrity. Their moderate toughness also allows for easy machining into complex shapes via turning, milling, or stamping, meeting diverse needs in precision counterweight designs. Compared to pure tungsten, tungsten alloys overcome brittleness, making them reliable counterweight components in high-stress scenarios. This combination of rigidity and flexibility outperforms traditional alloy materials in industrial applications.

Typical Models of CTIA GROUP LTD High-Density Tungsten Alloy Discs:

90W7Ni3Fe: Tensile strength (PSI) 900–1000, elongation 18%–29%

97W2Ni1Fe: Tensile strength (PSI) 920–1100, elongation 6%–13%

Strong Environmental Adaptability: The high-temperature resistance and corrosion resistance of tungsten alloy discs ensure stability in extreme conditions. With a melting point of 3,422°C, tungsten provides structural stability under high-temperature conditions, such as in high-temperature machinery or aviation engine components, where it can endure thermal loads without deforming or degrading. Its natural resistance to acids, alkalis, and salt spray makes it suitable for marine engineering and chemical equipment environments. Additionally, the wear resistance of tungsten alloys ensures long-term reliability in high-friction or vibration scenarios.

Eco-Friendly Characteristics: Compared to traditional lead-based counterweight materials, tungsten alloys offer higher density while avoiding the toxicity of lead, aligning with modern industrial demands for environmental protection and sustainability.

II. Applications of Tungsten Alloy Discs: From Precision Instruments to Heavy Equipment

CTIA GROUP LTD tungsten alloy discs are applied across multiple fields for counterweight purposes, playing a key role in regulating the center of gravity and enhancing stability, from small sports equipment to large heavy machinery.

Applications in Sports Equipment

In the sports equipment sector, tungsten alloy discs optimize weight distribution through counterweight design, improving user control and performance.

Tennis Rackets: Tungsten alloys are integrated as counterweight strips or embedded blocks in racket heads or handles. By adjusting the position and weight of the tungsten alloy, players can optimize racket balance and striking power based on personal preferences, enhancing shot stability and precision while maintaining a lightweight design for improved swing flexibility and comfort.

Golf Clubs: Tungsten alloys are embedded in club heads to adjust the center of gravity. Their high density allows weight increases without enlarging the head volume, optimizing swing trajectories and ball launch angles. This design boosts ball speed and flight distance while improving club stability for more consistent shots.

Applications in High-End Equipment

In high-end equipment manufacturing, tungsten alloys serve as counterweights to optimize dynamic performance and stability.

Racing Dynamics Optimization: In the racing industry, tungsten alloys are used in chassis, crankshaft, or wheel hub counterweight designs to optimize vehicle center-of-gravity distribution. Their high density enables efficient weight allocation in limited spaces, effectively suppressing excess vibrations and enhancing dynamic balance and handling stability. The superior wear resistance and corrosion resistance of tungsten alloys ensure reliable performance under high-speed driving and harsh road conditions, providing robust support for racecar performance.

Precision Machining Assistance in Machine Tools: In precision machine tools, tungsten alloys are used to balance rotating components or tool systems, reducing vibration and deviation during machining. Their high density and uniform weight distribution effectively minimize cutting force fluctuations, improving machining accuracy and surface quality.

Applications in Heavy Machinery

In the heavy machinery sector, tungsten alloys provide a foundation for the stable operation of large equipment. For instance, in cranes, excavators, or industrial presses, tungsten alloys act as counterweight blocks to balance the movement trajectories of heavy components, reducing vibration and mechanical stress. Their high density enables maximized weight support in confined spaces, while their excellent corrosion resistance ensures long-term stability even in outdoor or harsh environments.