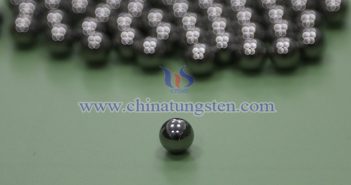

Tungsten cemented carbide balls are primarily composed of tungsten carbide (WC) powder as the main component, with metals such as cobalt (Co), nickel (Ni), or molybdenum (Mo) as binders, manufactured through powder metallurgy processes such as vacuum sintering. This composite material, due to its unique microstructure, performs exceptionally well in high-temperature environments, effectively resisting thermal deformation and oxidation. It is widely used in high-temperature and high-pressure applications such as the petroleum, chemical, and aerospace industries. 1. High-Temperature Resistance Mechanism and…