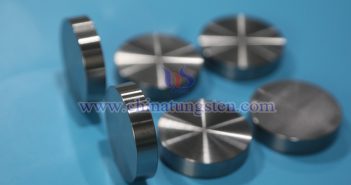

Tungsten alloy discs, owing to their unique physical and chemical properties, are increasingly widely used in counterweight applications, particularly excelling in high-demand scenarios such as aerospace, automotive industry, precision instruments, and sports equipment. With their high density, high strength, corrosion resistance, and excellent processability, tungsten alloys have become the preferred material for counterweights. In the aerospace sector, counterweight components are crucial for the balance and stability of aircraft. Due to their high density and compactness, tungsten alloy discs are commonly…