Tungsten carbide molds combine extremely high hardness, strength, and wear resistance, as well as excellent compressive strength and stability, making them widely used in metal forming, stamping, drawing, cold heading, and the manufacture of wear-resistant parts.

Key Features:

- Ultra-High Hardness and Wear Resistance: Tungsten carbide's hardness is second only to diamond, allowing molds to maintain stable dimensional accuracy and forming quality over long periods of use.

- Excellent Compressive Strength: Tungsten carbide molds maintain excellent performance under high loads and high impact conditions, making them suitable for complex working conditions.

- Strong Dimensional Stability: Tungsten carbide molds are less likely to deform during processing, ensuring precise forming and reusable parts.

- Long Lifespan: Compared to traditional alloy steel molds, tungsten carbide molds offer significantly longer service life, effectively reducing production costs.

Applications:

- Metal Forming: Used in stamping dies, drawing dies, cold heading dies, and other applications, widely used in automotive, machinery, and electronic parts manufacturing.

- Precision Machining: Suitable for demanding electronic component molds and precision hardware molds.

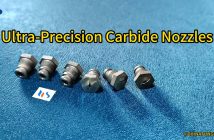

- Wear-Resistant Parts: Suitable for wear-resistant parts such as punch pins, ejectors, guide bushings, and punches.

- Special Applications: Used in high-strength mold applications under extreme conditions in the aerospace, energy equipment, and military industries.

With the upgrading of the manufacturing industry, tungsten carbide molds are moving towards finer grain sizes, higher toughness, and composite coatings to meet the needs of high-speed machining, forming difficult-to-machine materials, and higher-precision production.