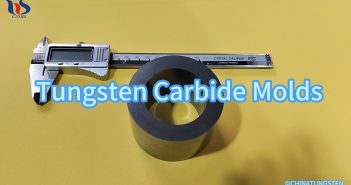

??????????????? Tungsten carbide molds combine extremely high hardness, strength, and wear resistance, as well as excellent compressive strength and stability, making them widely used in metal forming, stamping, drawing, cold heading, and the manufacture of wear-resistant parts. Key Features: Ultra-High Hardness and Wear Resistance: Tungsten carbide’s hardness is second only to diamond, allowing molds to maintain stable dimensional accuracy and forming quality over long periods of use. Excellent Compressive Strength: Tungsten carbide molds maintain excellent performance under high loads and…